|

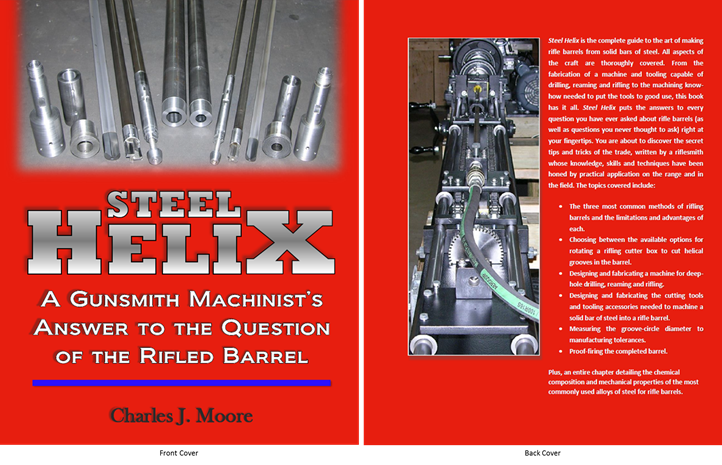

Mass-produced rifles are so readily available these days that few bother to think about how rifle barrels are made. However, for a variety of reasons, many of us choose to learn the secrets of the riflesmith in order to fabricate our own custom rifle barrels. My own desire to learn how to drill, ream and rifle a barrel from a solid bar of steel came from my quest to find a truly accurate large-bore muzzleloader. After years of frustrating searching, I finally realized that, if I really wanted such a rifle, I was going to have to build it myself from scratch. That decision was the beginning of a journey that spanned years before reaching the destination. The journey still isn’t over and likely never will be; there is always something new to learn and another new gunsmithing technique to try. But I have traveled far enough along the road to acquire a sound, working knowledge of the landscape. Now, in an effort to serve as a guide for like-minded machinists, I have compiled my experience into a comprehensive body of work on the subject of fabricating rifle barrels. The topics covered include:

· The methods available to create rifle barrels with modern machine tools · The four most common methods, both old and new, to rotate a rifling cutter box during the cut-rifling operation · Designing and fabricating a machine capable of drilling, reaming and rifling a solid bar of steel · Designing and fabricating the cutting tools necessary to carry out the required machining operations · A full discussion of the steel alloys that are commonly used to make rifle barrels · Proof-firing practices and procedures for both centerfire and muzzleloading rifles

Click here to view a free PDF Website Preview of Steel Helix. Click here to read the review of Steel Helix that appeared in Machinist's Workshop. |

|

Never before has all of the information needed to fabricate rifle barrels from solid bars of steel been presented in one volume of work. Until now, it took years of gathering data from several different sources to learn everything that is required to successfully fabricate rifle barrels. This book was written in an effort to condense and compile all of the machining know-how of the barrel maker into a single, comprehensive reference. Everything that the home shop machinist needs to know to start making his own custom rifle barrels is right here in the pages of Steel Helix.

Some authors have written a catalog of the commercial machinery and tools

that are used in making rifle barrels, but that kind of listing amounts to

little more than a description of mass-production industry. That’s not what

the home-machinist or dedicated rifleman is looking for. Other authors have

considered writing down all of the information required to teach someone

everything they will need to know to drill, ream and rifle their own gun

barrels. But, for a variety of reasons, they have chosen not to do so. In

the book

Modern Gunsmithing, copyrighted and first published in

1933 with co-author Clyde Baker, Colonel Townsend Whelen had the following

to say on the subject:

"We debated a long time as to whether we would include

instructions for boring, reaming, and rifling barrels in this book, and we

decided not to for several reasons. These operations are a separate art in

themselves, and a very specialized art in these days. To describe them

would require several hundred pages, and such description would be

intelligible only to a trained machinist or toolmaker, who alone is

competent to undertake such work. While it is possible for a very skilled

and ingenious machinist to set up an engine lathe to bore, ream, and rifle

a barrel, yet generally speaking, heavy and expensive special machine

tools are necessary for this work, and these are far beyond the resources

of the small professional or amateur gunsmith, necessitating a large and

expensive layout which must be in addition to a general purpose machine

shop, the latter being needed for related work and for tooling up for the

rifling operations. Even a very modest equipment may easily run to $25,000

or higher. The various boring bits, reamers, and rifling cutters cannot be

bought, but must be made, hardened, and ground by the workman himself, who

must have the necessary skill. Such skill cannot be taught in any book,

but requires years of training in general machine work.

The Colonel makes some very good points; creating rifle barrels does

indeed require specialized equipment and specialized machining skills that

are beyond the comprehension of the average person. However, I know for a

fact that an ordinary gunsmith machinist

can learn to make

all of the machinery and tooling required to craft rifle barrels from

solid bars of steel. I know this to be true because I am just such a

machinist. If you’ve read this far, there’s a fair to middling chance that

you are as well. The skills

necessary to master the specialized art of drilling, reaming and rifling

gun barrels can be learned by anyone who sets his mind to the task and

refuses to accept anything less than complete success in his endeavors. |